|

Features |

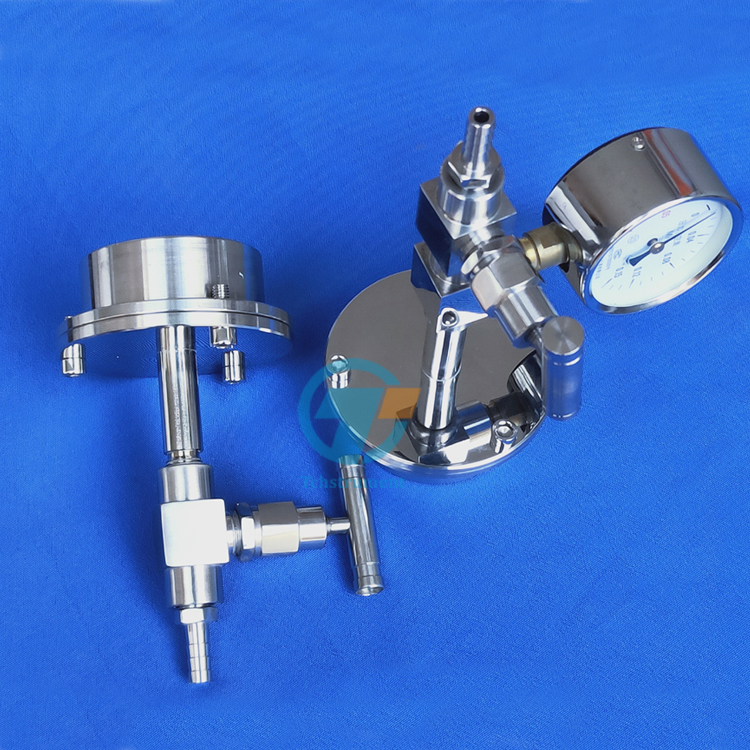

· Seal tube by tightening screws on the flange without any welding or gluing. · Excellent for any type of tubing: ceramic, glass, quartz and steel pipe. · Installation requires drilling holes on the furnace casing to mount the flange support. · Made of Stainless Steel (SS304) with high-temperature silicon O-rings on each flange. · Delicate metal support allows for both vertical and horizontal adjustment · The openable flange is designed for sample easily loading/unloading. · Designed for 100mm vacuum tube furnace to seal both ends of OD100-102 mm tube without any welding and gluing. |

|

Descriptions |

· The left end comes with a hinged flange with a barbed valve, 1/4" feedthrough and pressure gauge. · Mechanical Pressure Gauge is available as an alterlative of regular gauge. · The right end comes with a hinged flange with a barbed valve and KF25 vacuum port. · KFD25 angle valve may require for connecting the vacuum port to a vacuum pump. Please choose the KF25 angle valve at the related product below. |

|

Vacuum level |

· 10E-2 torr by a mechanical pump · 10E-5 torr by a small turbopump · 10-6 torr by hi-speed turbopump |

|

Application Note |

· Place the o-ring on the notch of the hinged flange. · A tube block is required behind each flange to avoid the silicone O-rings melting. · In the parts diagram on the left, the dia# is 80 for this product. · Tube block is available in related products below. · Please do not over tighten the three hex screws on the flanges to avoid overpressure incidents. The recommended torque is 35~40 inch-lbs. · For liability considerations,we do not recommend or endorse the use of any toxic, flammable or corrosive gases with our flange assemblies. Please contact us with any concerns. |

Note: We supply OEM service, customized size flange can be designed according to your need!