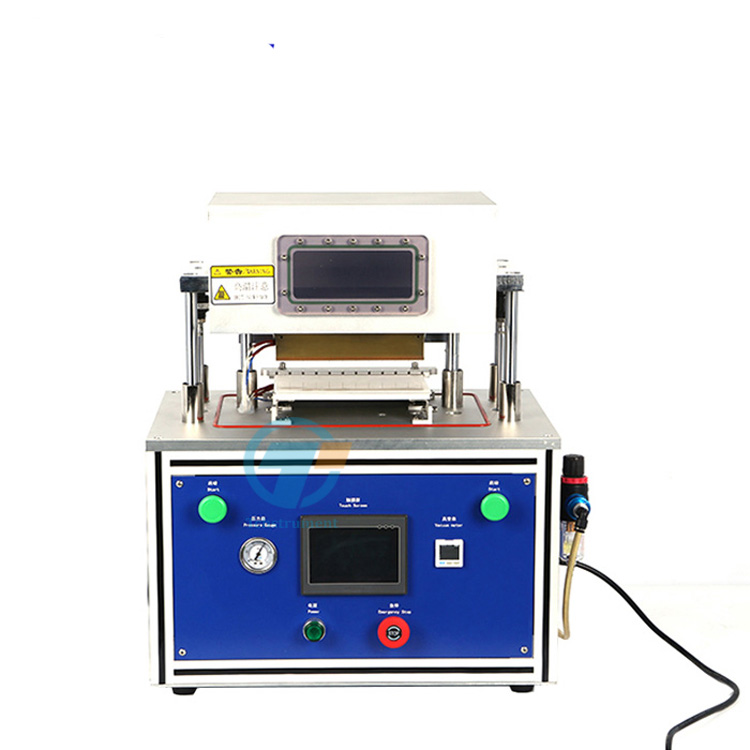

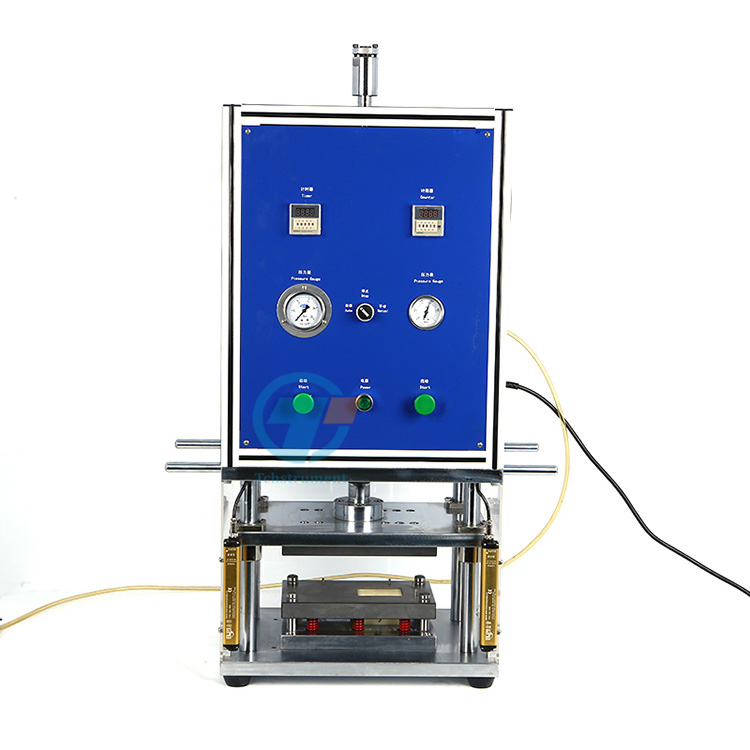

Product introduction: This stacking machine is mainly used for the Z-shaped stacking assembly of the positive electrode, negative electrode and separator of lithium battery Manual loading, subsequent pole piece position correction and stacking process are completed automatically, with high stacking efficiency and high accuracy. Cells up to 150*150mm can be stacked, and different sizes can be realized by adjusting the fixture, which is very suitable for the development and sample production of stacking lithium-ion batteries. The equipment adopts a single cantilever structure design, automatic constant tension control of the coil isolation film, and automatic correction control.

Main features:

*Automatic servo constant tension control of the roll diaphragm.

*Diaphragm automatic photoelectric correction control.

*The number of stacking layers can be automatically controlled according to the pre-setting

*Adopting compatibility design, battery size change can be realized by adjusting the positioning fixture, and the adjustment range is large;

*PLC control, HMI operation, easy to use and maintain;

*Pole pieces are manually loaded, automatically positioned, the robot automatically sucks the pieces, and automatically stacks;

*Left and right movement is controlled by pulse motor, which is precise and convenient for fine adjustment.

Specification

|

stacking method |

Continuous "Z" fashion stacking |

|

Working Voltage |

AC220V 50/60Hz |

|

Power |

1KW |

|

Stackable Size Ef electrode |

Min. L40mm *W40mm, Max. L150mm*W150mm

|

|

Stackable Layers |

Up to 500 layers |

|

Stacking thickness |

Max.30mm |

|

Aligning Accuracy |

±0.3 mm for stacked electrodes |

|

Acceptable Separator Roll Size |

O.D<9.8'' (250mm)

|

|

Suggested Air Pressure |

0.5 - 0.8 MPa (Air compressor is not included in the standard package. |

|

net weight |

about 285kg |

|

Dimension |

L1000mm*W780mm*H1050mm |