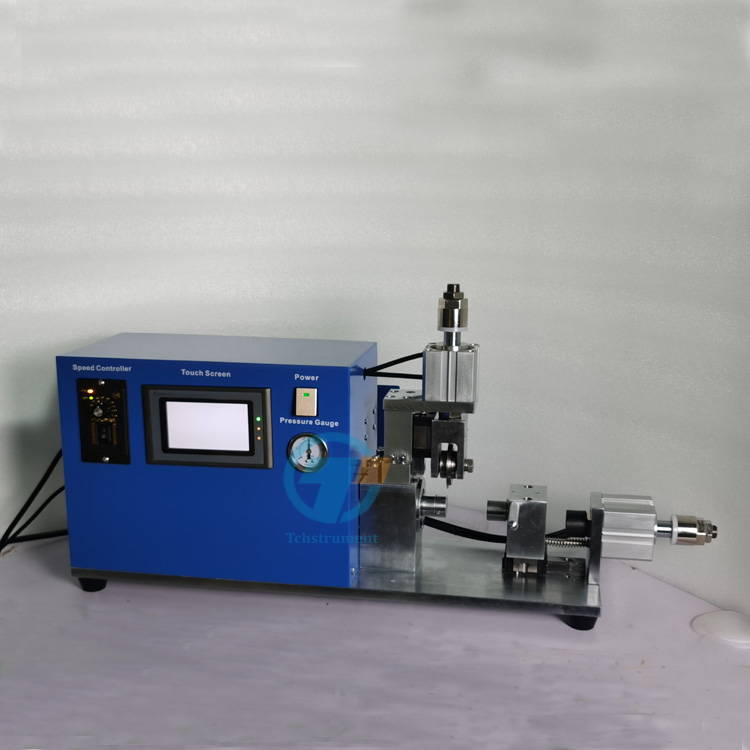

This product is mainly used for battery injection, with high injection accuracy, easy adjustment and fast efficiency. It is suitable for various cylindrical battery cell cases injection including CR123,18650 26650, 32650 and AA with changing clamps.

As to the Vacuum injection, the number of batteries in the tray: 80, divided into two vacuum boxes B, each vacuum box can be placed in one tray, 80 batteries per tray, a total of 160batteries can be placed at the same time.

Equipment characteristics and working principle:

1. The liquid injection machine adopts imported PLC and human-machine interface centralized control, which is easy to operate. You can set the injection speed and injection times.

2. The evacuation time and nitrogen release time can be arbitrarily adjusted, the number of liquid injection rows, and the cell separation distance. Left and right shifts are driven by stepper motors,

3. The vacuum still box is independently controlled. The upper and lower vacuum hoods are all operated by cylinders. Vacuum and dry gas are automatically exchanged.

4. Stepping motor is used with Buco brand

5. 5.7-inch touch screen, well-known brand of Buco

Specification

|

Model |

TCH-JK-ZYJ-02 |

|

Power |

about 1.5KW |

|

Voltage |

204-240V, 50/60HZ |

|

Injection accuracy |

determined according to the injection accuracy of the Seamaster pump (± 0.02g) |

|

injection times |

adjustable from 1 to 10 times |

|

Injection volume |

set according to Seamaster pump (single time 0-7g) |

|

Left and right injection times |

single cycle (the number of cycles can be adjusted) |

|

Working efficiency |

30 ~ 80 pcs / min (conventional cylinder, square according to actual situation); |

|

vacuum degree |

-0.1Mpa |

|

Compressed air |

0.3 ~ 0.6Mpa |

|

Working clamps |

18650 battery tray 6 rows and 8 columns, a total of 48 battery stations |

|

warranty |

1 year , with whole lifespan maintenance |